Description

Coriolis mass flowmeter for advanced process applications

- High accuracy (±0.05% flat) for cryogenic to HT media (-200…+400°C / -328…+752°F); maintains operation over a wide range of gas fractions and complex flow conditions (EGMTM)

- SIL 2/3; CT: OIML R117, R137, MI-005, MI-002; API, AGA; hygienic certifications

- Flange: DN10…300 / ½…12″, max. PN 160 / ASME Cl 1500

- 3 x 4…20 mA, HART®7, Modbus, FF, Profibus-PA/DP, PROFINET, EtherNet/IP™, Bluetooth®

Overview

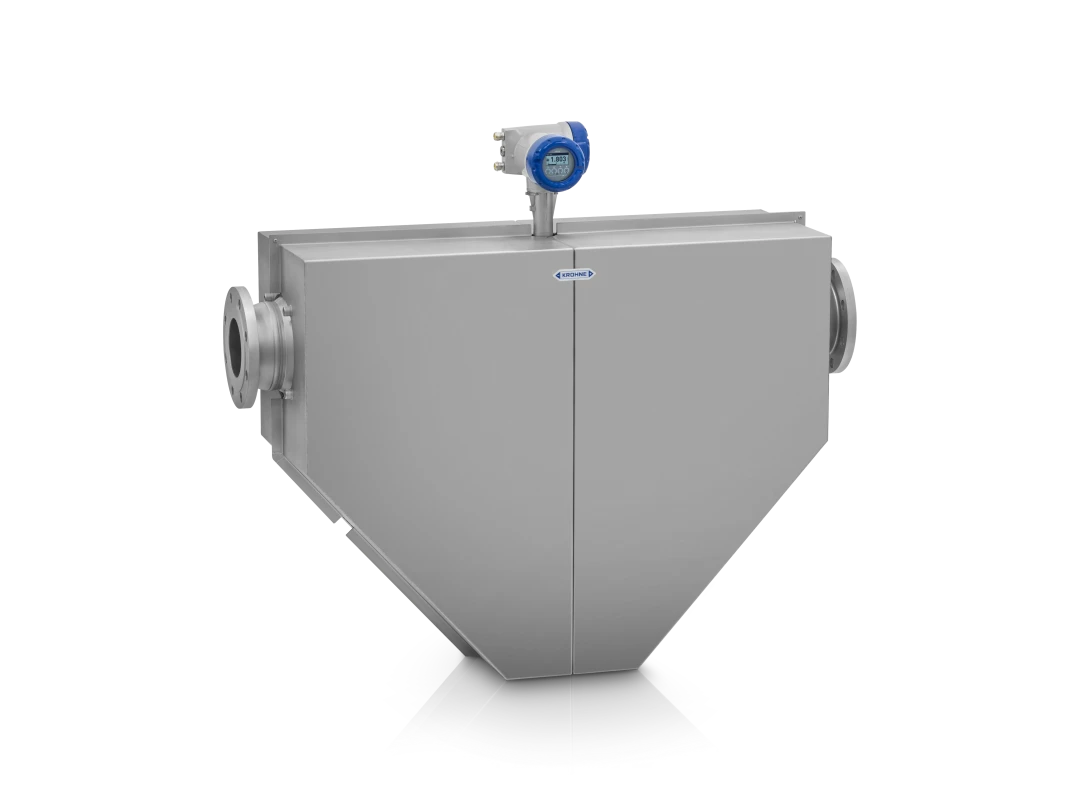

The KMS 6400 is the industry-standard Coriolis mass flowmeter renowned for its exceptional performance in the process industry. This twin-bent tube meter delivers superior accuracy and performance across various applications.

From precise process control within the (petro)chemical sector to concentration measurements in the food and beverage industry and even to custody transfer, filling, and transport measurements in the oil and gas sector, the KMS 6400 is the trusted choice.

Moreover, its high-end features extend its versatility, making it the ideal instrument for challenging scenarios, including cryogenic applications like Liquefied Natural Gas (LNG), with temperatures plummeting to -200°C / -328°F. It is equally proficient in applications with extreme operating temperatures, reaching 400°C / 752°F, and high pressures, soaring up to 200 bar / 2900 psi. Whatever your industry demands, the KMS 6400 delivers.

Features & Options

– Innovative twin bent tube design.

– Entrained Gas Management (EGMTM) ensures seamless operation even when air or gas is present in the medium.

– Unparalleled wireless accessibility: the sole Coriolis mass flowmeter on the market offering secure Bluetooth® access or remote connectivity via HART® for safety-related applications.

– Easily commission, verify, diagnose, and monitor your device with a secure wireless Bluetooth® connection (within a range of <20 m / 65.6 ft).

– Achieve SIL 2/3 certification for sizes up to DN200 / 8″.

– Experience the convenience of a partial proof test with PTC (Proof Test Coverage) of up to 82%.

– Swift and fully digital signal processing for optimal performance.

– Benefit from integrated temperature measurement.

– Minimize pressure loss with the optimised flow splitter design.

– Opt for high-precision mass, density, and volume flow measurement with an optional accuracy of ±0.05% of MV.

– Meet the highest OIML accuracy class of 0.3 for custody transfer (CT).

– Access comprehensive sensor and process diagnostics, including NE 107 compliance.

– Choose from three different sensor materials, including Duplex and alloy 22.

– To suit your needs, explore various options, such as heat tracing and purge ports.

– Ensure self-draining when mounted vertically for efficient operation.

– Experience immunity to crosstalk and resistance to installation and process-related effects.

– Conduct on-site flowmeter verification effortlessly with the OPTICHECK service tool.