Precision and Control for Admixture Batching

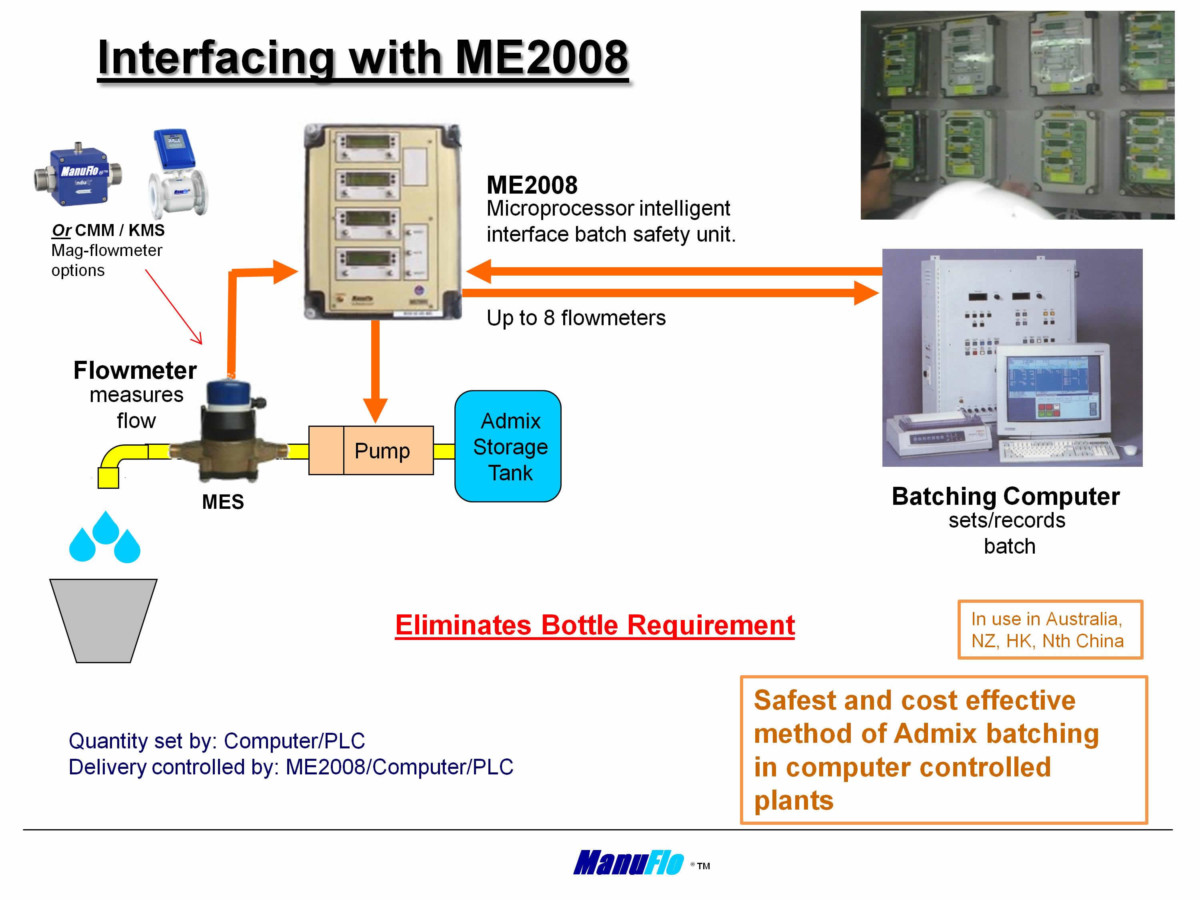

The ME2008 interface brings advanced control and safety features to batching plants. Designed to integrate with flowmetered systems, the ME2008 allows for precise dosing of admixtures in concrete or other industrial processes. The system is PLC/computer-controlled, offering a seamless interface between batch controllers and flowmeters for automated, reliable batching.

Key Features:

- Enhanced Safety: The ME2008 interface includes safety batching cards that prevent unauthorized or incorrect batching, ensuring operational safety.

- Accurate Flowmeter Control: Integrates with a variety of flowmeters to provide real-time, accurate control of admixture dosing.

- PLC/Computer-Controlled Integration: Compatible with modern batching plants, offering full automation and control.

- Multiple Model Options: Available in a range of configurations to suit different batching plant needs.

- Seamless Integration: Works with both PD meters and magnetic flowmeters, giving operators the flexibility to choose the best flow measurement option.

ME2008 Interface Overview

The ME2008 Interface Safety Batching Card offers a reliable and secure way to control the dosing of admixtures. When connected to flowmeters and PLC/computer systems, the ME2008 ensures precise control and safety throughout the batching process.

Batching Control

With the ME2008 interface, batching becomes a hands-free process, controlled by the PLC or computer system. The safety card ensures that batches are executed according to the set parameters, preventing over-batching or under-batching.Safety Features

The interface includes several fail-safes to ensure the batching process is safe and secure. This prevents operator error or system malfunctions that could affect batch quality.Installation and Configuration

The ME2008 is easy to install, with clear instructions provided in our Install Guide. The interface card is compatible with various batching plant configurations and can be paired with different flowmeter types.

How It Works:

- Setup: Install the ME2008 interface with your PLC or computer system, and connect the flowmeters to the system.

- Flowmeter Monitoring: The system tracks the flow of admixture in real-time, providing accurate data to the batch controller.

- Batch Completion: When the target amount is reached, the ME2008 interface ensures that the flow is stopped automatically, preventing over-batching.

The ME2008 allows for complete automation, ensuring accurate dosing and eliminating the potential for human error in the batching process.

Why Choose the ME2008 System?

ManuFlo’s ME2008 interface provides reliable and precise control for automated batching plants. By integrating flowmeters and PLC/computer-controlled systems, we deliver the ideal solution for ensuring safe and efficient admixture dosing. The ME2008 interface and associated flowmeters allow for high-precision control, making it the preferred choice for batching plants requiring accurate admixture management.

ME2008 Interface Safety Batching Card

Contact Us

Frequently Asked Questions (FAQs)

Q1: What are the main benefits of using the ME2008 interface?

A: The ME2008 interface provides precise and reliable control for admixture batching. It enhances safety, offers real-time monitoring, and integrates easily with flowmeters and PLC/computer systems for a fully automated solution.

Q2: What flowmeters can be used with the ME2008?

A: The ME2008 is compatible with a wide range of flowmeters, including MES20-N, MES-P, MES20-S-T, and magflow meters such as AMM-v2, CMM, and KMS502-F. These flowmeters provide precise measurement to ensure accurate admixture dosing.

Q3: What safety features does the ME2008 include?

A: The ME2008 comes with a safety batching card that prevents unauthorized or incorrect batching, ensuring that only the correct amount of admixture is added to each batch.

Q4: Can the ME2008 interface be integrated with a PLC system?

A: Yes, the ME2008 is designed to integrate seamlessly with PLCs or computer-controlled systems. It allows for full automation of the batching process and can be customized to meet the specific requirements of your system.

Q5: What are the available models for the ME2008 series?

A: The ME2008 series includes various models such as ME2008-1A-2A-3A, ME2008-1A-2D-3C, ME2008-1B-2B-3B, and others. These models offer different configurations to suit various batching plant setups.

Q6: How difficult is it to install the ME2008?

A: The ME2008 is designed for easy installation, and we provide detailed installation guides to assist in the setup. It can be integrated into both new and existing batching systems.

Q7: Is there support for different flowmeter sizes?

A: Yes, the ME2008 system supports a wide range of flowmeter sizes, from small 15mm meters up to 150mm magflow meters. This flexibility allows it to handle various flow rates depending on the batching plant’s needs.

WHY CHOOSE MANUFLO?