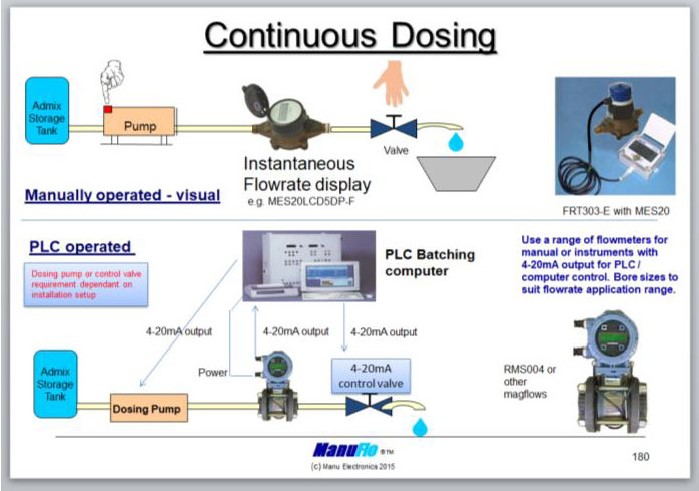

Solutions for Precise and Consistent Dosing

ManuFlo’s Continuous Dosing Systems ensure accurate and consistent chemical dosing. These systems are available in both manual and automated setups. Whether you need a simple flowmeter or an advanced automated solution with magnetic flowmeters, we offer reliable solutions for industries that require precise chemical control.

Key Features:

- Consistent Dosing: Achieve steady flow and precise dosing with continuous monitoring.

- Manual and Automated Options: Choose between manual systems or automated setups, depending on your specific needs.

- High Accuracy: Our flowmeters and controllers offer real-time monitoring to ensure accurate dosing.

- Flexible Integration: Compatible with a wide range of flowmeter options, from PD meters to advanced magflow meters.

How It Works

Manual Operation (MESLCD6 or MESLCD4-F)

The operator uses the LCD display to monitor flow and manually control the dosing process. This ensures the desired flow rate is maintained.Automated Operation (FRT303 with MES-P or Magflow Meters)

The flowmeter continuously monitors flow rates and sends real-time data to the FRT303 controller. The system automatically adjusts the flow to maintain a consistent dosing rate.Seamless Integration

Whether manual or automated, our systems can integrate easily into your existing setup. This ensures smooth and accurate dosing every time.

Why Choose ManuFlo’s Continuous Dosing Systems?

- Versatile Solutions: We offer both manual and automated systems to fit your specific needs.

- Precise Control: Our flowmeters and controllers provide real-time monitoring, ensuring accurate dosing for your processes.

- Reliable Performance: Built to withstand industrial environments, our systems offer long-lasting durability.

- Easy Integration: Our continuous dosing systems integrate smoothly with existing PLC or control systems, making it easy to implement in your workflow.

Continuous Dosing Systems

Contact Us

Frequently Asked Questions (FAQs)

Q1: What is the difference between manual and automated continuous dosing systems?

A: Manual systems, such as those using MESLCD6 or MESLCD4-F, require an operator to monitor and control the flow. Automated systems, like FRT303 with MES-P or magflow meters, handle the dosing process automatically, ensuring a consistent flow without manual intervention.

Q2: Can I upgrade a manual system to an automated system?

A: Yes. You can integrate an FRT303 controller with your existing flowmeters or install advanced magflow meters to upgrade to an automated system.

Q3: What types of flowmeters are compatible with continuous dosing systems?

A: Our systems are compatible with MES-P, MESLCD6, MESLCD4-F, and advanced magflow meters such as MM, RMS, and KMS502.

Q4: What industries can benefit from continuous dosing systems?

A: Continuous dosing systems are widely used in industries such as concrete, chemical manufacturing, water treatment, food & beverage, and pharmaceuticals.

Q5: How accurate are the magflow meters in automated systems?

A: Magflow meters such as MM, RMS, and KMS502 provide highly accurate, non-invasive flow measurement. This makes them ideal for industries that require precise dosing.

WHY CHOOSE MANUFLO?