Innovative and Reliable Solutions for Accurate Admixture Dosing

At ManuFlo, we specialize in providing top-quality flowmetering, batch control, and PLC interface equipment for accurate measurement and dispensing of construction chemical admixtures. Our solutions are trusted across industries in the Asian, Australian, and Pacific regions, with customers in South America, the Middle East, and Europe.

With over 40,000 flowmeters, 15,000 batch controllers, and 5,000 interface cards installed worldwide, we are a leading provider for concrete batch plants, production plants, mobile tankers, and on-site construction projects.

Explore our range of admixture dispenser systems to find the best solution for your needs.

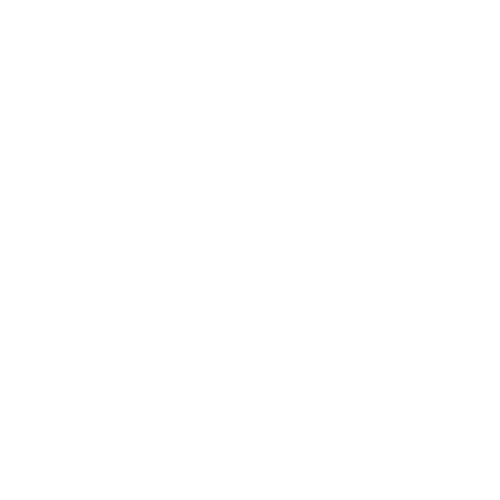

Manual Batching Solutions

Manual Chemical Transfers with Flowmeters

Our manual batching solutions are designed for simple and reliable admixture transfers. Operators manually control the process, ensuring accuracy through high-quality flowmeters.

- Flowmeter Options:

- Battery-Powered LCD Reset PD Meters:

- Models: MESLCD6, MESLCD4

- Sizes: 20-40mm

- Magflow Meters (AC/DC Powered):

- Models: ME5-T, FRT303 with AMM-v2, CMM

- Sizes: 15-25mm

- KMS102 Magflow Meters:

- Sizes: 4-150mm

- Battery-Powered LCD Reset PD Meters:

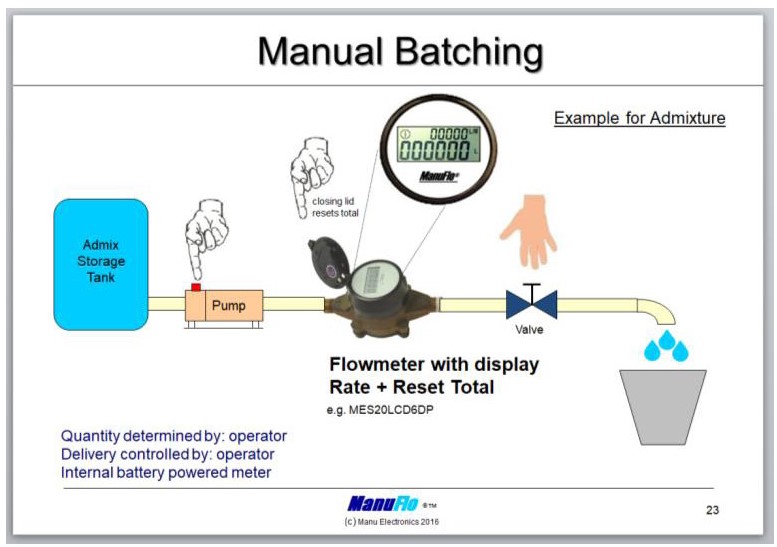

Automatic Batching Solutions

Preset Batch Control for Precise Admixture Dosing

Our automatic batching systems offer precise and hands-free dosing through advanced batch controllers and flowmeters. Operators can preset the desired batch amount, and the system will ensure accurate dosing.

Batch Controllers:

- ME995 Series:

- Models: ME995-1A, ME995-2, ME995-3, ME3000

- Preset Panel Mount Controller: Includes IP65-rated enclosures for harsh environments.

- ME995 Series:

Flowmeter Options:

- MES20-N / MES20-S-T (20mm)

- MES-P (20-40mm)

- AMM-v2, CMM Magflow (15, 20, 25mm)

- KMS502 Magflow (4-150mm)

Portable Trolley Batch System

Mobile Admixture Batching for Flexible Operations

The Portable Trolley Batch System (PTBS) is perfect for job sites where mobility is essential. This system offers a compact, easy-to-move solution that allows for on-the-go admixture batching with precise control.

- Features:

- Portable design for flexible use across multiple locations

- Integrated with battery-powered flowmeters for accurate dosing

- Robust and durable for industrial applications

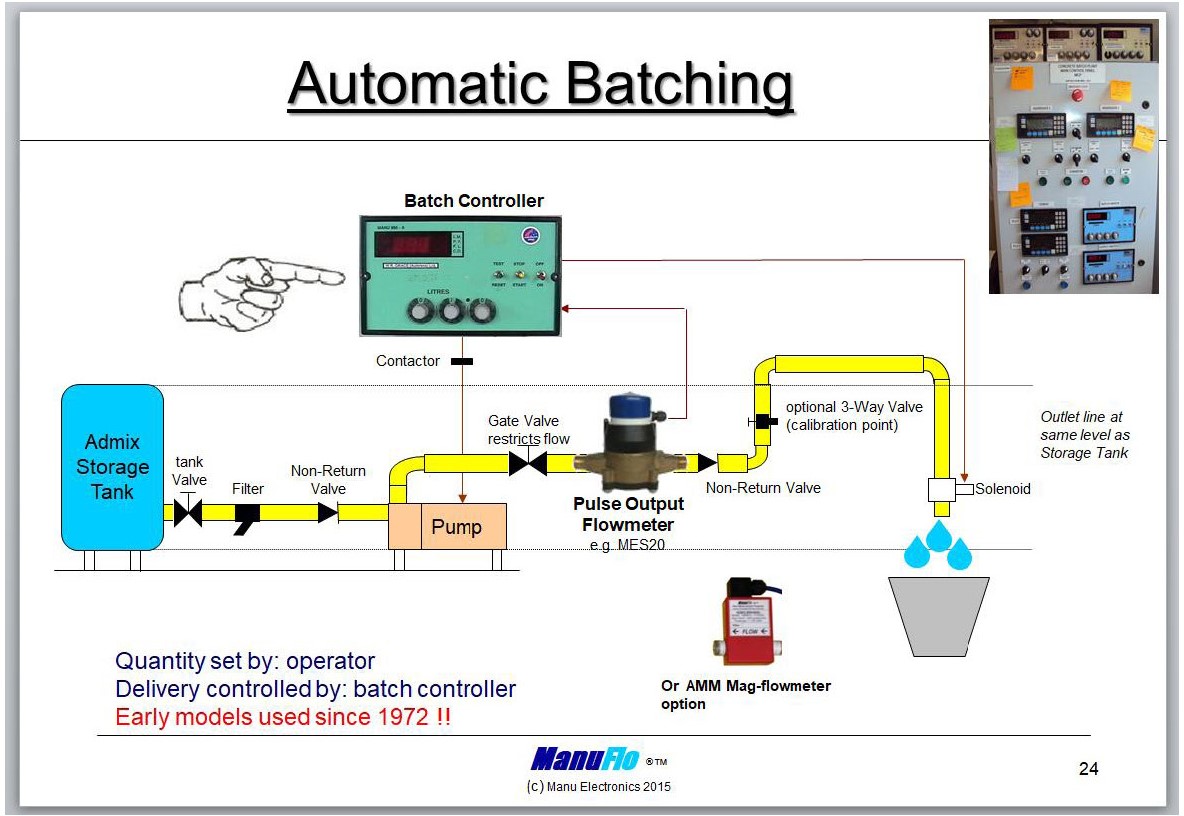

Batching Plant Monitoring Systems

Real-Time Monitoring for Admixture Dosing

Our batching plant monitoring solutions provide continuous oversight of admixture dosing at concrete batching plants. With real-time data and advanced safety features, you can ensure accuracy and safety for every batch.

ME2008 Interface Safety Batching Card:

Designed to ensure safe batching processes with flowmeters.Flowmeter Options:

- MES20-N / MES20-S-T (20mm)

- MES-P (20-40mm)

- AMM-v2, CMM, KMS502 Magflow

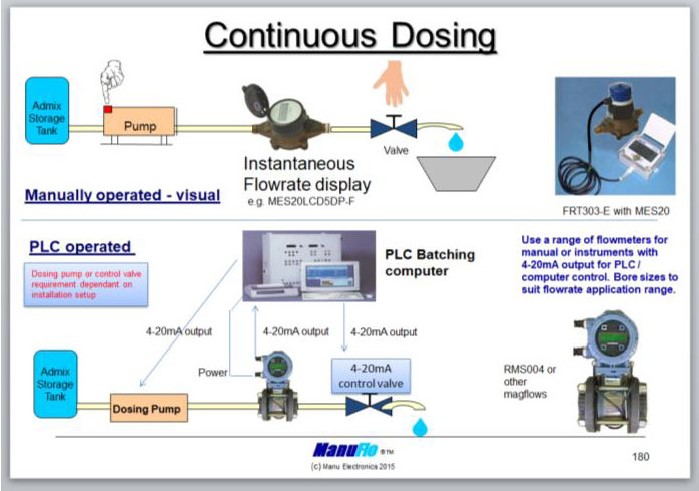

Continuous Dosing Systems

Manual and Automated Solutions for Consistent Dosing

Our continuous dosing systems ensure precise, ongoing chemical dosing for industries requiring steady admixture flows. Available in both manual and automated configurations, these systems provide flexibility while maintaining accuracy.

- Manual Flowmeter Options:

- MESLCD6, MESLCD4-F

- Automated Systems:

- FRT303 with MES-P Flowmeters

- FRT303-MES System with digital integration for full automation

- Magflow Options:

- MM Magflow, RMS Magflow, KMS502 Magflow (4-150mm)

Industry Applications

ManuFlo’s admixture dispenser systems are used in a wide range of industries, including:

- Premix Concrete Plants

- Admixture Production and Distribution

- Mobile Tanker Operations

- Construction Sites

- Shotcrete and Grout Applications

WHY CHOOSE MANUFLO?