Description

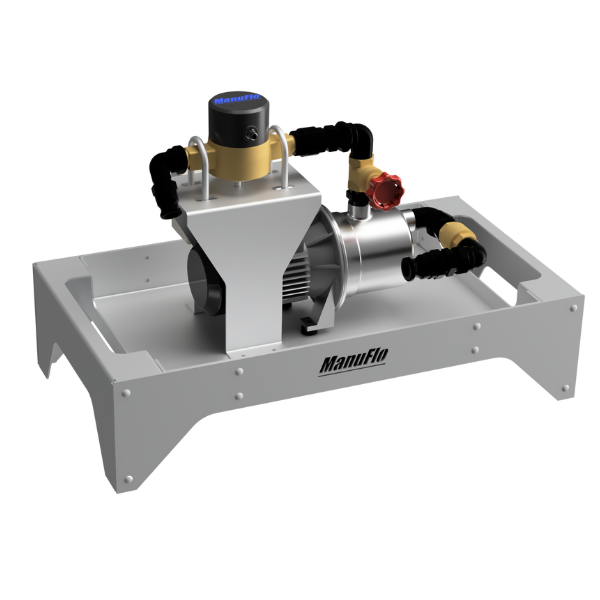

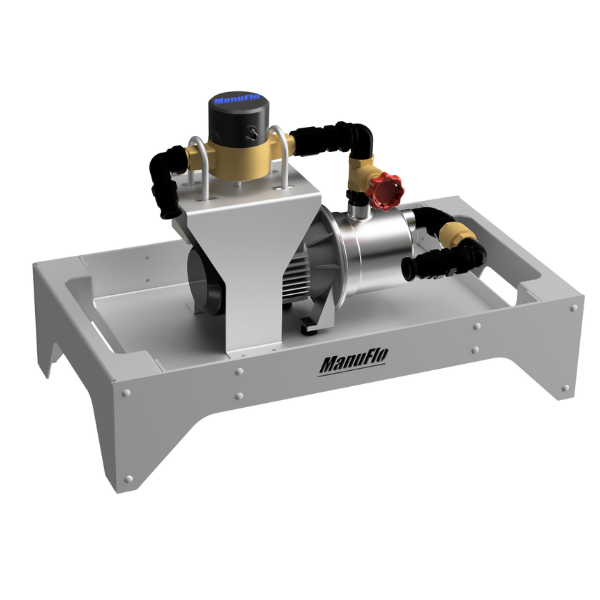

The ManuFlo Admixture Batching System (ABS) is a pre-wired, pre-tested dosing package engineered to simplify admixture dispenser installation and deliver consistent, high-accuracy performance for concrete batching plants.

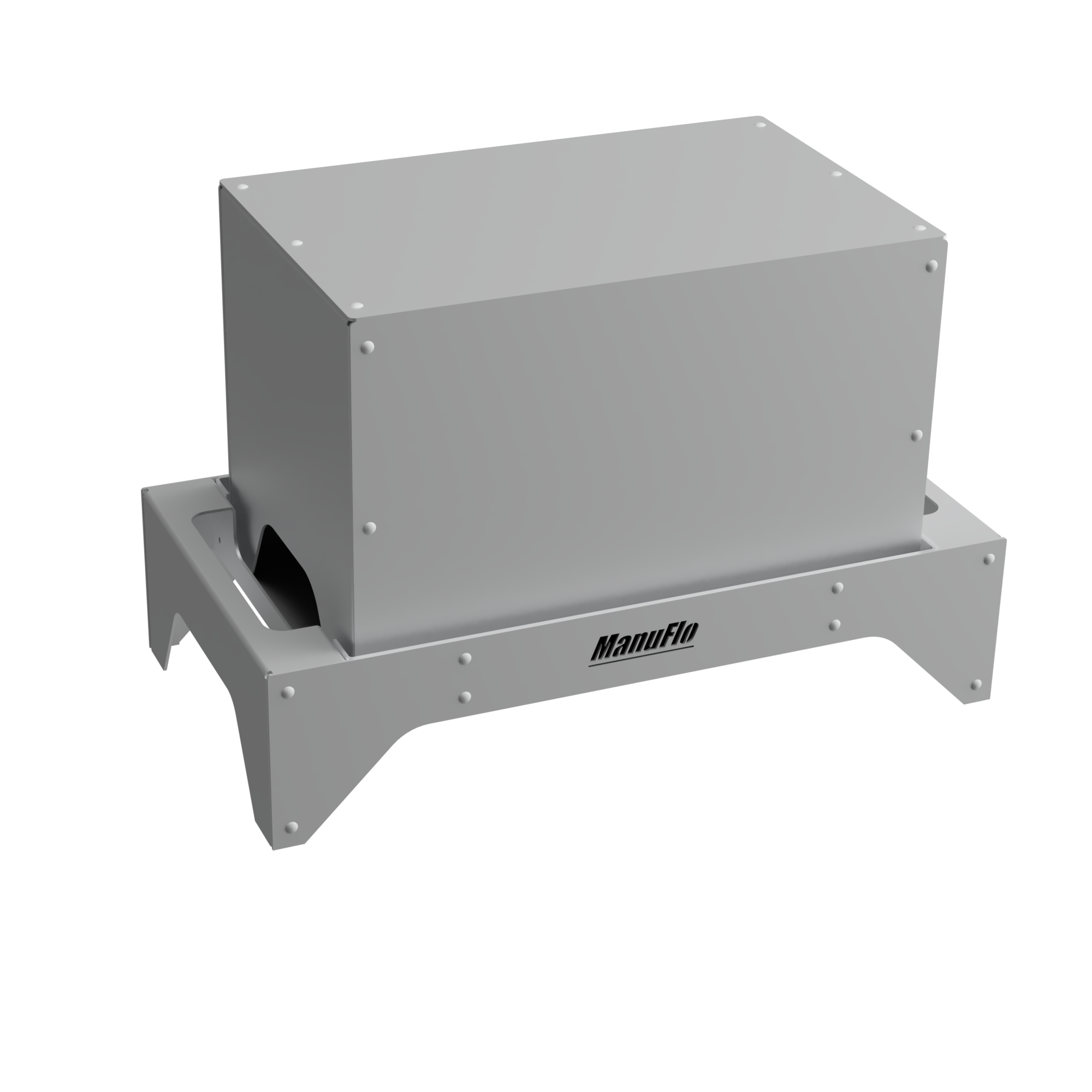

Built around a single-stage jet-assisted centrifugal pump, the ABS provides dependable pressure and flow for a wide range of admixtures with minimal maintenance. A rugged aluminium maintenance case protects components and ensures easy servicing.

Key Components

Pump – High-performance centrifugal pump delivers reliable pressure and flow, with optional Positive Displacement Pump (PPD) upgrades for high-specific-gravity chemicals or fast-flow requirements.

Flowmeter – Choice of MES20-HD, MES25-HD, or CMM25 (MiniMag) flowmeters for precise liquid measurement across a wide flow range.

Valves – Adjustable control valve regulates flow, while a non-return valve guarantees measured admixture flows directly to the mix.

Controller Interface – Compatible with ManuFlo batch controllers for seamless batching control and data recording.

Performance Highlights

Flow capacity: up to 80 L/min

Pressure head: up to 42 m

Operating pressure: up to 600 kPa (140 kPa max suction)

Temperature range: ambient up to 50 °C; water up to 45 °C

Advantages

Fully integrated, ready-to-install system saves time on site.

Accurate flow measurement reduces admixture waste and ensures consistent concrete quality.

Durable construction for long life in demanding plant environments.