The rise of telematic systems has transformed how businesses monitor and manage operations, especially for equipment, fleet, and fluid management. As industries increasingly rely on data for decision-making, the need for precise, real-time fluid monitoring has become more critical. Flowmeters play a vital role in this approach by providing accurate fluid measurements that optimize processes and reduce costs.

In this article, we’ll explore the essential role flowmeters play in telematic systems, why accuracy matters, and how they can impact operations across industries like construction, agriculture, fleet management, and manufacturing.

How Flowmeters Fit into Telematic Systems

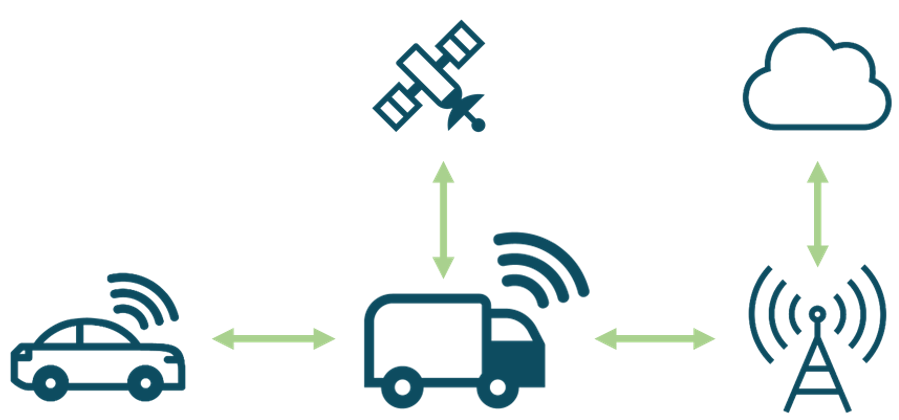

Telematic systems collect data from sensors on equipment, vehicles, and machinery. These systems track various parameters, including location, engine health, and fluid consumption. Flowmeters are responsible for measuring the rate and volume of fluid flow.

When integrated with telematics, flowmeters deliver the data needed to:

- Track Fluid Consumption in Real-Time: Displaying fluid levels and usage on telematic dashboards provides operators with instant visibility.

- Optimize Resource Management: Knowing how much fluid is being used helps businesses minimize waste and allocate resources efficiently.

- Monitor Equipment Health: Variations in fluid consumption can indicate potential issues, allowing early detection and resolution.

Why Accurate Flowmeters Matter in Telematic Systems

Accuracy is essential for effective fluid management. Without precise data, businesses risk inefficiency, higher costs, and even equipment damage.

Why Accuracy is Crucial:

- Informed Decision-Making: Real-time, accurate data allows businesses to make better decisions about resource allocation, reducing the chances of shortages or overuse.

- Cost Control: Accurate fluid monitoring prevents waste, which helps businesses manage operating costs, whether reducing fuel usage in vehicles or managing water in agriculture.

- Improved Maintenance: Unusual fluid flow patterns, such as spikes or drops, can indicate equipment issues. Accurate flowmeters detect these anomalies early, allowing preventive maintenance.

How Flowmeters Improve Efficiency in Various Industries

Flowmeters enhance efficiency across multiple sectors by providing accurate fluid data:

1. Construction

In construction, heavy machinery relies on fluids like fuel, water, and admixtures. Flowmeters help track fluid usage, ensuring machinery runs efficiently without unnecessary refueling or fluid shortages.

2. Agriculture

Water and fertilizers are critical resources in farming. Flowmeters allow farmers to monitor these resources and ensure optimal application. When integrated with telematics, flowmeters offer real-time control over irrigation and fertilizer usage, improving crop yields while conserving resources.

3. Fleet Management

Fuel efficiency is a key factor in transportation. Flowmeters integrated with telematic systems provide live data on fuel consumption, allowing fleet managers to optimize routes, reduce fuel costs, and lower carbon emissions.

4. Manufacturing

In manufacturing, fluids like water, coolant, and chemicals are essential for production. Flowmeters track fluid usage in real time, ensuring a consistent supply and preventing production delays. Accurate monitoring also supports sustainability efforts by reducing waste.

Choosing the Right Flowmeter for Your Telematic System

Selecting the right flowmeter ensures reliable data and seamless integration with telematic systems. Key factors to consider include:

- Compatibility: The flowmeter must be compatible with your telematic platform to enable smooth integration.

- Accuracy: Precision is vital for informed decision-making based on fluid data. Choose a flowmeter with highly accurate readings.

- Durability: The flowmeter must withstand harsh conditions, such as high-pressure environments or abrasive fluids.

- Low Maintenance: Opt for a flowmeter that requires minimal upkeep to reduce downtime and operational costs.

At Manuflo, our high-performance flowmeters are designed for seamless integration with telematic systems. They provide the accuracy and durability needed to manage fluid resources effectively across industries.

The Future of Flowmeters in Telematic Systems

As telematic systems evolve, the integration of flowmeters will continue to advance. Expect to see more:

- IoT Connectivity: Flowmeters will become part of larger Internet of Things (IoT) networks, allowing businesses to gather and analyze data from multiple devices in real time.

- AI-Powered Analytics: Artificial intelligence will offer predictive analytics that help businesses prevent equipment failures, optimize fluid consumption, and reduce costs.

- Automation: Future telematic systems may automatically adjust fluid flow based on real-time conditions, enabling a fully automated resource management system.

Conclusion: Maximize the Value of Telematics with Flowmeters

Flowmeters are essential components of any data-driven telematic system. Their ability to track fluid consumption in real time, improve resource management, and identify maintenance issues early helps businesses operate more efficiently and reduce costs.

If you’re looking to enhance your telematic system with precise flow measurement, contact Manuflo today. We offer flowmeters tailored to meet the needs of various industries, ensuring your operations run smoothly.

Frequently Asked Questions

Q: How do flowmeters work with telematic systems?

A: Flowmeters measure fluid flow and transmit the data to telematic systems, providing real-time insights into fluid consumption and equipment performance.

Q: What are the benefits of using flowmeters in telematics?

A: Flowmeters enhance fluid monitoring, improve resource management, reduce costs, and allow early detection of maintenance issues.

Q: Can Manuflo’s flowmeters integrate with existing telematic systems?

A: Yes, Manuflo’s flowmeters are designed to integrate seamlessly with most telematic platforms, providing real-time monitoring and data transfer.