Description

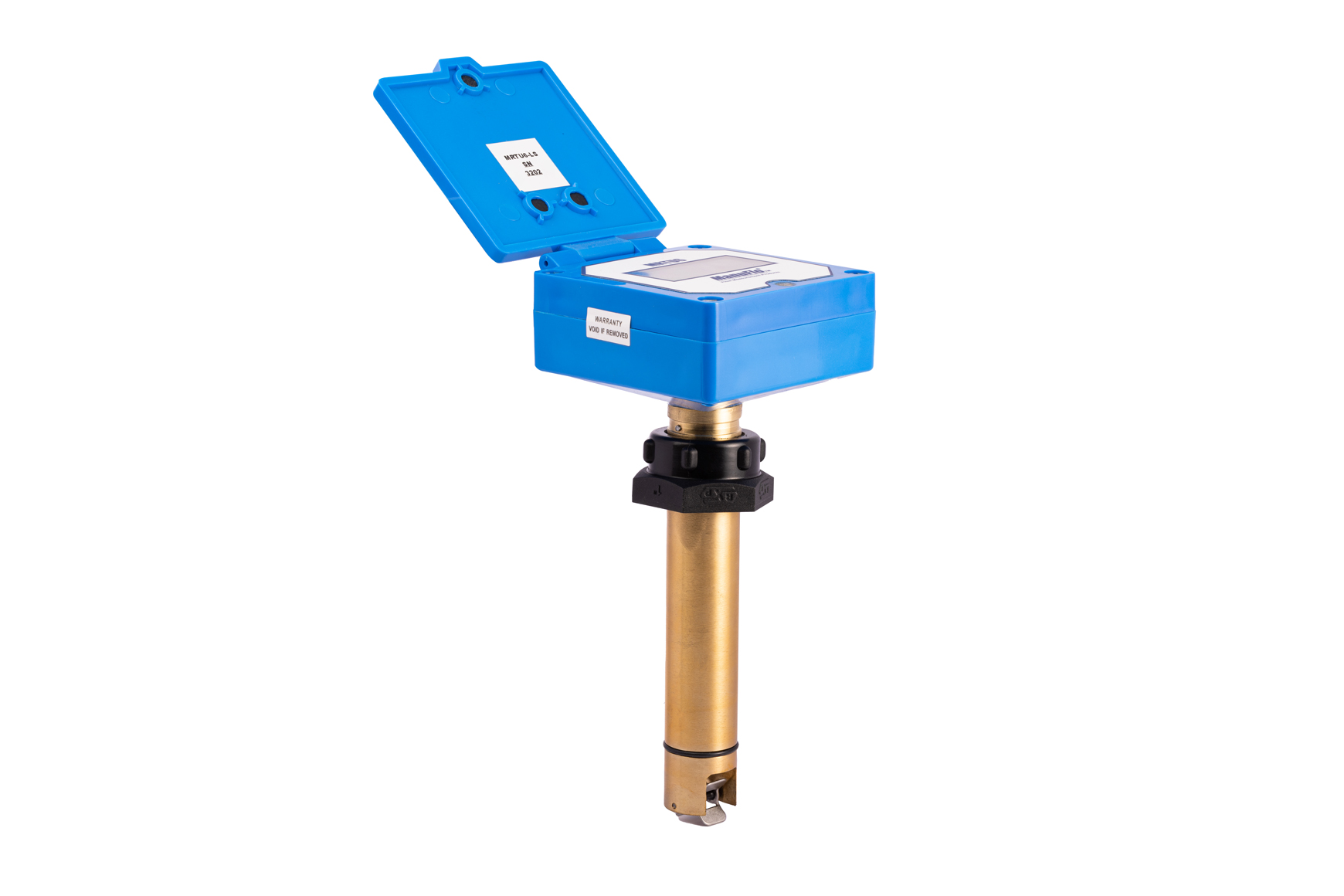

MRTU4-F : LCD Flow Rate Monitoring Flowmeters (Universal Slip Insertion Paddlewheel)

The MRTU4-F flow rate monitor is designed and manufactured in Australia by ManuFlo. The MRTU4-F has a unique ‘quick release’ slip insertion stem section designed to be inserted to the ManuFlo 1” nipple adaptors (part BSPB etc) which allows the display head to be fitted to most 1” BSP female entries. Usually, the MRTU4-F is pre-fitted with a ManuFlo ‘T’ piece pipe adapter, adapters are available for a range of pipe sizes from 20 to 315 mm diameters, and the adapter range includes Galvanized Iron tees, Class18 Cat19 PVC high pressure tees, and saddle-clamp agricultural poly-pipe fittings, the advantage being we pre-install the MRTU4-F for you on to the fitting and pre-calibrate on our NMI certified test rig (sizes 20mm – 100mm) to obtain the best K- factor value. Or optionally you may purchase our BSPB or BSPB-LS pipe adaptor nipples (1” BSP M external thread) in brass or optional version BSPSS in 316 SS material.

The MRTU4-F is suitable for medium to high flow range liquid flow measurement applications. Being internally battery powered, the unit is ideal in situations where no external power supply is accessible, making them totally portable Flow Rate monitoring flowmeters and with optional pulse output to data logger or PLC. NOTE: As standard the pulse output is live even when lid is closed however this feature can be disabled by adding -PNL (pulse is disabled when lid closed) to the order code.

The flowmeter’s only moving part (a stainless steel alloy rotor which turns as liquid flows past it) allows registration in Litres/minute (L/M) or Litres/second (L/M) with optional decimal place on the 4 digit Liquid Crystal resettable display counter. The main body component, consisting of the electronic counter board, is housed in a robust ABS-UV resistant IP65 lower enclosure and ASA-UV upper enclosure. The LCD display is visible through the toughened Polycarbonate window and sealed by a recessed gasket and 4 stainless steel screws. A special scratch resistant film allows optimal reading even in the harshest conditions. The impact resistant ASA-UV lid protects the LCD from prolonged sun exposure, contaminants and breakage.

To operate, open the hinged lid to view the LCD display which will indicate Flow Rate once liquid reaches velocity sufficient to turn the rotor blades. The internal lithium battery has a typical life of 8+ years depending on environmental conditions.

FEATURES

- 4 digit LCD Flow Rate indicator (20mm high, 7 segment)

- Flow Rate in Litres/minute (as standard) or optional Litres/second.

- ± 2.5% accuracy, at 0.7 – 8.0 m/s flow velocity

- Repeatability: ± 1.0%

- Internal 3.6 v Lithium Battery (8+ year life).

- Max. Process Temperature 80 °C

- Max. Ambient Temperature 55 °C

- Max. Operating Pressure: PVC Tee’ options rated to 1100 kPaAll Metal Tee options are rated 2000 kPa

- With simple installation pipe fittings/adapters.

- For pipe sizes from 20 to 100 mm

- Optional pulse output, via M12 IP67 plugset

- New Robust ASA-UV IP65 Display housing

- Dual Hinged robust lid protects LCD from sunlight, with magnet secure function.

- Slip insertion sensor design with locking cap allows simple removal from pipeline if cleaning rotor.

- Easy Access for re-calibration and user friendly smart 1 point re-calibration function –self calculation for a new K- factor.

- Optional External re-calibrate via Portable Device with RFID and EWM calibration software.

- Large Display: Reset Total 4-digit LCD (20mm high) counts in LITRES.

- Pulse Output is Disabled when lid is closed (code -PNL), or Live even when lid is closed (code –P).

- Option for continuous Live LCD (code -NS)